WORK PLAN

The ambitious project objectives towards durability-lifetime of stacks for heavy duty trucks require a strategic approach in terms of improved material and operation strategy level.

Activities within the project are divided into one management and four technical work packages. Tasks in technical WPs will take place in parallel. The project is divided into three phases: the initial phase focuses on gaining understanding of degradation modes in heavy duty applications. Therefore, an innovative multi-scale and multi-domain modelling framework for virtual MEA analysis is going to be built up. The second phase will focus on advancing and improving MEA materials. In the third phase those models and material improvements will be validated on the fuel cell test rig.

WORK PACKAGES

This work package includes coordination and management activities as well as dissemination and exploitation tasks. The goal is to provide efficient project structures, to manage resources and results against the defined project plan and to avoid risks.

Dissemination helps to promote the project and to bring the results to various stakeholder groups (such as research peers, industry and other commercial actors, professional organizations, policymakers, etc.) in a way to enable them to use the results in their own work. Exploitation explains the use of the results during and after the project end. Therefore, plans for dissemination and exploitation will be created in the course of the project. There will be, in both cases, an initial a final dissemination / exploitation plan prepared by the consortium. These deliverables will summarize the beneficiaries’ strategy and concrete actions related to the protection, dissemination, and exploitation of the project results.

Leader: AVL, UL

The focus and aim of WP2 is the understanding of degradation mechanisms relevant for HD vehicles. Thereby, specific test protocols will be defined for SoA MEAs and new materials/MEAs developed in WP3. Based on performance and AST data, a modelling framework will be developed to simulate MEA degradation based on stack operating conditions, to project the performance after 30,000 h of operation, and to develop mitigation strategies to reach the durability target. The following tasks will be performed:

- Development of test protocols for SoA MEAs based on the analysis of aged cells/stacks

- Development of specific test protocols specific for down-selected new materials in WP3

- Modelling framework development for virtual MEA analysis

- Simulation of the degradation of SoA MEAs and MEAs with newly developed materials, aiming to project HD stack performance after 30,000 h for different operating conditions

- Recommendations for material selection, mitigation strategies, and ADTs

Leader: TUM

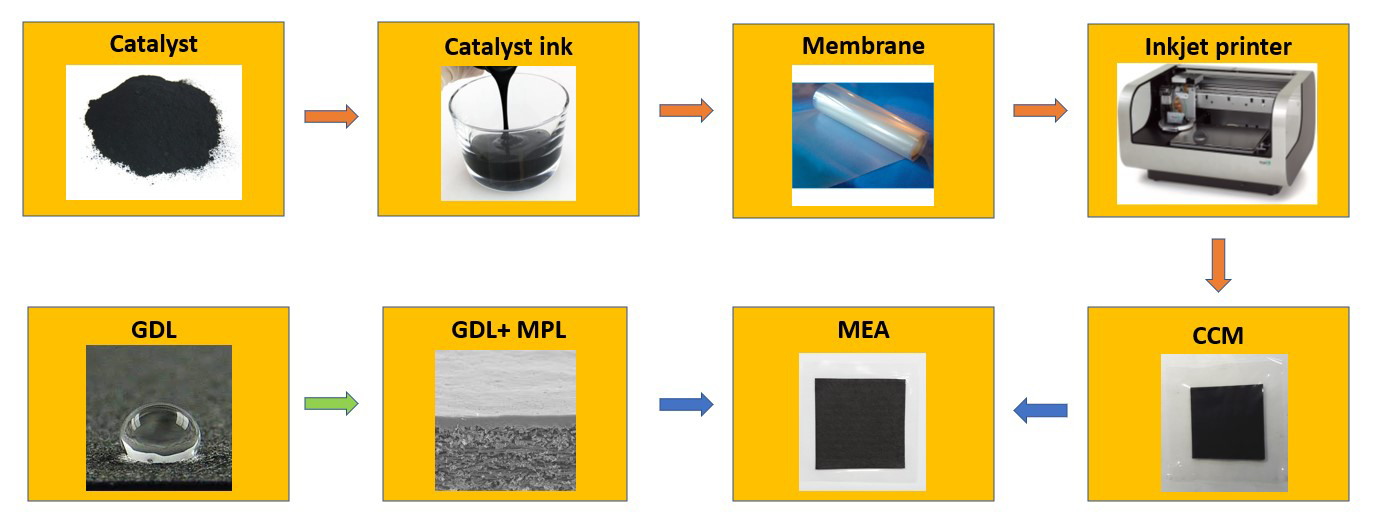

Develop, realize and validate breakthrough MEA. Use of innovative mitigation strategy to substantially reduce MEA degradation in HDV driving cycle tests and prolong durability to 30.000 h. These MEAs will be tested by project partners in WP4. Based on the results from these tests, advanced materials and process steps for new high performance MEAs will be developed. The work is distributed among 6 tasks:

- Preparation of two primary catalyst concepts based on validated technology

- Catalyst coated membrane preparation on two selected membranes

- GDL+MPL optimisation

- MEA integration for single cell tests

- MEA materials and processing optimisation

- MEA integration for short stack testing

Leader: Mebius

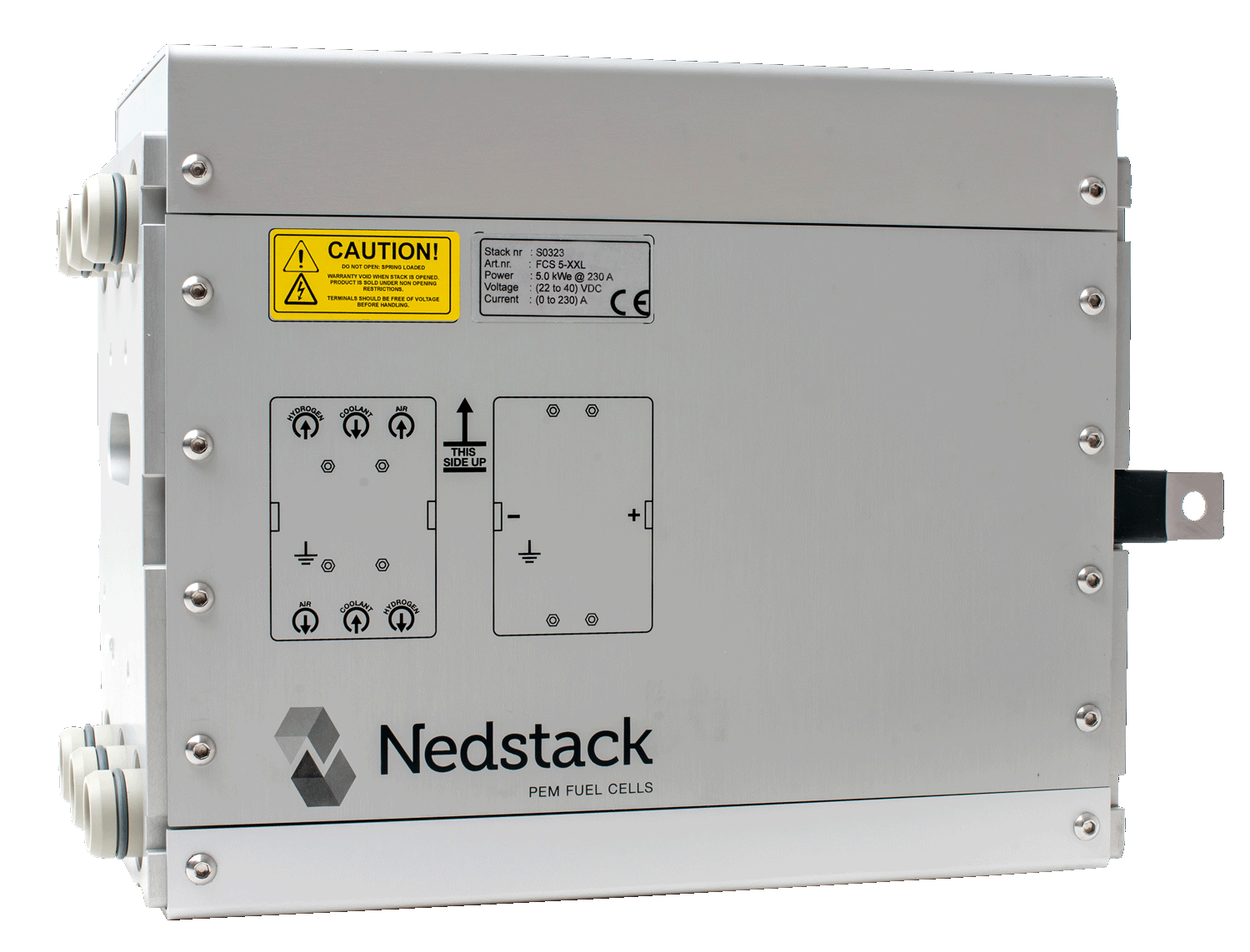

The focus and aim of WP4 is the evaluation of materials for reference developed in WP3 through tests according to the protocols defined in WP2. The performance and durability assessment, evaluation and verification will continue through all three phases of MORELife. Thereby, the materials will be preselected based on the prospect of meeting performance and durability targets for implementation in the targeted >10-cell short stack. The following tasks will be performed:

- Acquisition of reference durability data and material characteristics from SoA materials through detailed analyses and ASTs

- Test protocol refinement based on experimental results

- Measurements from single cell to short stack level

- Implementation of developed materials in industry relevant hardware in a >10-cell (or >1 kW) short stack

- Material functionality proven

- Data input for model based lifetime assessment

Leader: NFCT

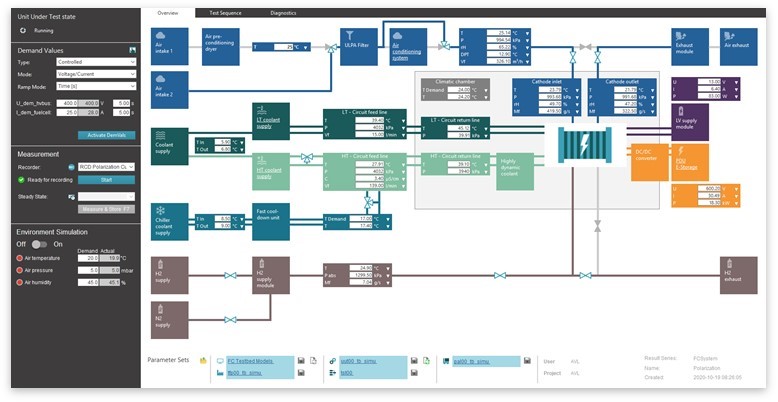

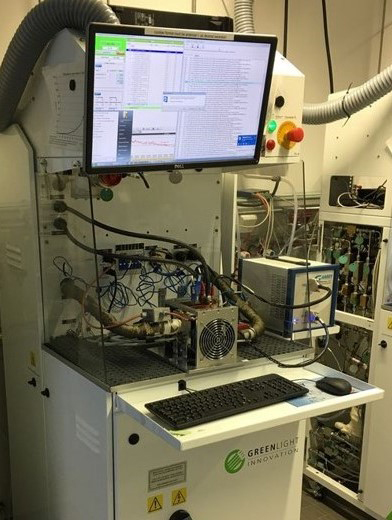

Within this work package the focus is on short stack testing, degradation analysis on stack level and operation validation in application relevant environment. Therefore, the following tasks will be addressed:

- Method development for online-diagnostics (gas analysis, electrochemical analysis, etc.) for degradation detection to overcome the constraints of the stack architecture with respect to diagnostics

- Combined lifecycle testing of short stack to identify degradation mechanisms in HD application based on results from cell level testing (WP2)

- Find optimal operating conditions and operation condition sensitivities of the stack

Leader: AVL